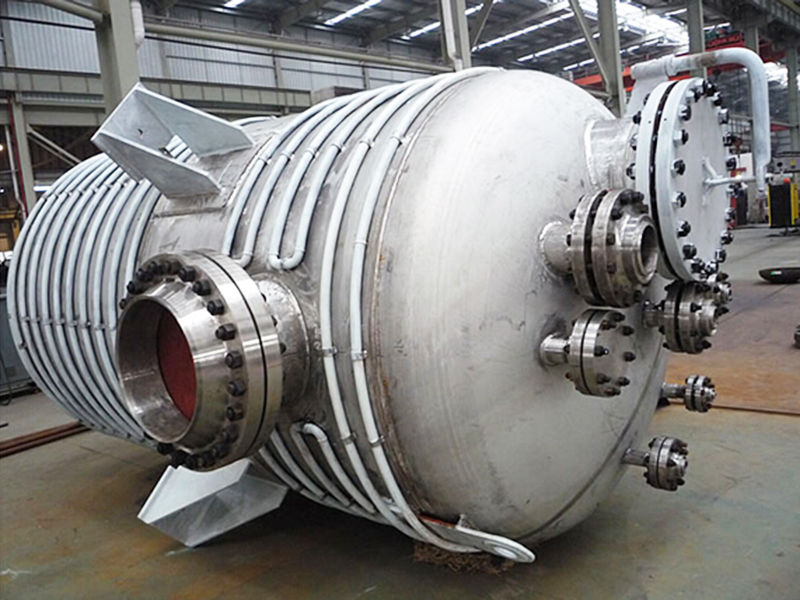

Determination of geometric characteristics and manufacturing parameters of reactors

The so-called geometric characteristics of the reactor mainly include the reactor type, impeller type, baffle type and the relative position of the accessories in the reactor and the size ratio, etc. What conditions must be met in all aspects?

Generally speaking, the diameter of the impeller and the diameter of the kettle used for different types of impellers are different; and in terms of the specific position of the impeller in the kettle, for a heterogeneous reaction system, when the stirring material is a suspended solid that is easy to settle, it is often Place the impeller close to the bottom of the reaction kettle or install a bottom baffle; for gas-liquid mixing, the air inlet is required to be close to the bottom of the impeller.

There is also the issue of the number of reactor impellers used, which is closely related to the ratio of liquid layer depth to reactor diameter. When the ratio between the two is greater than 1.25, multiple impellers should be used. The specific number is determined based on the ratio of the water depth equivalent to the cauldron diameter.

In addition, before the reactor is manufactured and used, its volume, reactor size, cylinder thickness and other parameters need to be determined. The calculation of the reactor volume is relatively simple. It only needs to be carried out material balance based on the reaction time, that is, the product. Got it.

During the specific operation, first calculate the processing volume of raw materials or product output per unit time, and then calculate the reaction time based on this, and determine the effective volume of the reactor based on the time. The full volume of the equipment is the effective volume divided by 0.6-0.8. That's it.

In companies that calculate the wall thickness of reaction kettles, there are more data designed, including nominal thickness, working pressure, nominal diameter, allowable stress, corrosion allowance and the sum of processing deviations, etc. Here, Only under this premise can the wall thickness of the reaction kettle body be calculated, thereby completing the production of the reaction kettle.