Steel Weldment Equipment for Rotary Refining Furnace For Copper Smelting

-

OEM Furnace with driving system and support roller used for copper smelting

Main material: High tension carbon steel, forging, casting.

Demand: precision on dimension control, experience on assembly and test for driving equipment.

- Send Whatsapp

- E-mail:heidi@js-ql.com

Detail

Description:

Steel Structure Furnace with Riding System for Copper Semlting on Metallurgical Industry

Main material: High tension carbon steel, forging, casting.

Demand: precision on dimension control, experience on assembly and test for driving equipment.

Company Information

Jiangsu Qiulin Special energy equipment joint stock Co.,Ltd founded in 2010, and mainly engaged in all kinds of non-standard vessels, cryogenic storage, coal water slurry complete equipment, steel structure etc. Qiulin employs advanced design capabilities,is equipped with modern manufacturing facilities,and a full range of in-house test equipment. Over the years, we adhere to the "customer-oriented" business philosophy to provide our customers with all kinds of equipment and have the competitive edge in quality, delivery and price.

Qiulin has been partner of many domestic and overseas famous company like CNPC, CNOOC, SINOPEC, Air Liquid, Air products, Yingde gases, Fuel Tech, ABB, Messer, Metso, Andritz, Reel, Morimatsu, Linder etc.

| Established | 2010 | ||

| Export rate | 30% | ||

| Site Area | 100000㎡ | ||

| Supply Scope | Pressure vessel, storage tanks, heat exchangers, reaction kattles, adsorber for air separation etc. Cryogenic liquid storage tanks, skid of gas production. Steel structure fabrication, steel structure equipment |

||

| Application | Oil and Gas, LNG and Marine , petrochemical, metallurgy, food and pharmaceutical, environmental protection | ||

| License | _Design and Fabrication License for Category I ,II & III (Class A1 and A2) of Chinese standard pressure vessel _ASME U,DOT/CNR _API, EN,AWS _ISO9001:2008, ISO14001:2004, OHSAS18001:2007 |

||

| Production capacity |

Monthly steel structure fabrication:3000T Maximum loading weight:200T Maximum diameter: 9.2M Lifting Height: 14M |

||

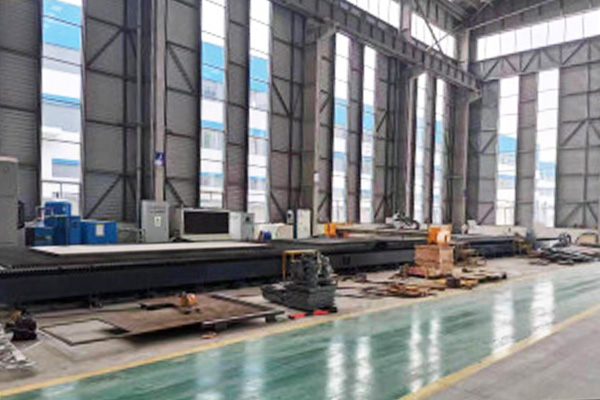

Fabrication Site

Equipment

|

|

|

|

| Laser Cutting machine | Milling machine L=12m | Automatic welding | H beam welding |

|

|

|

|

| Horizontal lather platform | Gantry boring and milling machine | CNC Milling machine | Vertical Lather dia.6.3m |

Fabrication workshop

Material test Lab

|

|

|

| Cooling equipment +impact test | Tensile test | |

|

|

|

| Chemical content test | Microscope | Hardness test |

Painting room and RT inspection Room

|

|

|

|

| Sandblasting room size 16mx40m Painting room size 16mx40m |

Three painting rooms size 16mx40m each |

Advanced UT/MT/RT equipment. 4 RT rooms, biggest one is 8mx24m |

|

Transportation

Typical project cases

|

|

|

|

| Metallurgical equipment-Mill | Metallurgical equipment | Metallurgical equipment Anode furnace |

Metallurgical equipment Kaldo furnace |

|

|

|

|

| OEM Skid Type Steel Structure | Box Steel Structure Frames | light steel mill building structure | Oil Rig platform |

Others products

|

|

|

|

| LNG tank | MT tanks | Absorption Tower | Reaction Kettle |